- Call Us On

+91 98229 14366

- Mail Us On

Pioneer in Aluminium Die Casting

Facilities

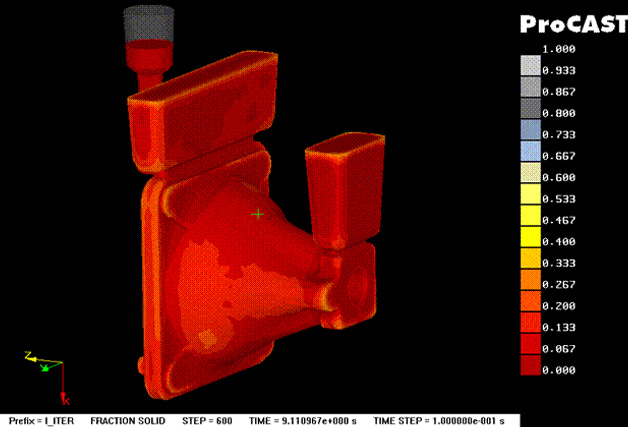

Design Capabilities

- 3D modeling on PRO-E, UG

- Thermal & Flow Simulation

- Machining Programs on DEL-CAM

In-House Tool Making Capability

In-house die and machining fixture facility allows us to become independent in our operations and maintains the confidentiality of our customer's products.

Foundry Capabilities

Permanent Mold Casting

- Monthly Melting Capacity 900 MT.

- 56 Permanent mold stationary, hydraulic operating (GDC) machines.

- 21 Tilt Pouring Machines (with PLC)

- Alloys Poured : AC4C, AC4CH, AC2B, AC4B, AC4D, AC2A

- Spectro for Chemical analysis

Heat Treatment

- Monthly capacity of 380 Mt

- Fully automatic process with digital recording of process data which enables us to document the measured results (SCADA).

- Process Conducted: T6

Machining Capabilities

We have variety of state of art machines which allow us to maintain tight tolerances for our casted components. We are equipped with 41 VMC's and 9 CNC machines from Chiron and Makino, Hass, Fanuk.

Quality Lab

We are equipped with all the necessary quality instruments like

- CMM : Hexagon, US Make , 1 nos

- Universal Testing Machine : 1 nos

- Specroschemical Metal Analysis System : 2 nos

- Tool Pre-setter, Zoller make, 2 nos

- Microscope for studying microstructure, 1 nos

- Boroscope, 1 nos

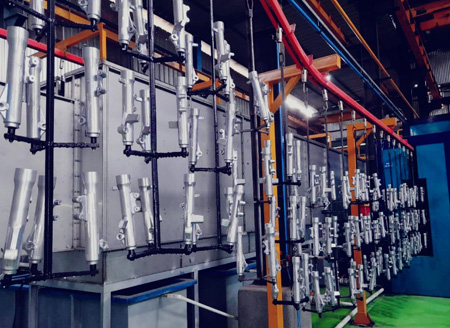

Powder Coating Plant